Additive Manufacturing (AM) and 3D Printing

Castle Microwave has a legacy of identifying and bringing new technologies to UK customers in the RF/Microwave market and we are now pleased to introduce Additive Manufacturing and 3D Printing capabilities to our customer base.

What is AM/3D printing?

3D Printing, also known as Additive Manufacturing, is the construction of a three-dimensional object from a CAD model. To realise a 3D Printed component, a variety of processes can be employed in which material is deposited, joined or solidified under computer control to create a three dimensional object, with material being added together (for example plastics, liquids, powder grains or metals being fused together), typically layer by layer.

In recent years, advances in 3D Printing technology has enabled the production of highly detailed components with features in the low microns, and by employing post processing techniques, this creates an excellent surface finish that provides a high level of effective conductivity, making the technology suitable for RF and Microwave applications

Focussed on high performance and high reliability systems employing RF and Microwave components, we offer a custom design capability based on individual requirements. Parts are manufactured in Aluminium, INVAR, PEEK or Titanium materials. Following printing, the parts are subject to chemical surface treatment and plating to improve surface finish and skin conductivity. On completion of post-processing, parts are tested to verify RF performance and ensure they meet customer specification.

What are the advantages of 3D printing?

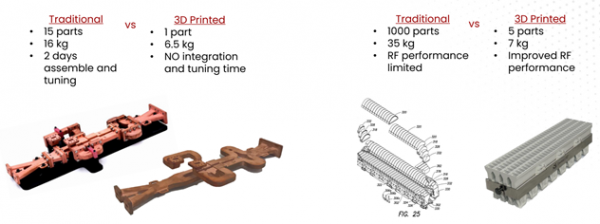

There are several advantages of utilising 3D Printing technology. These include reducing the number of piece parts required to realise a complex structure or signal path, savings in weight (an important consideration for flight and space flight applications), greater structural integrity, and the ability to print parts that are difficult or even impossible to produce using traditional machining methods.

Two examples are shown below:

What parts can be manufactured in 3D?

The versatility of 3D printing enables various types of RF and microwave components to be produced including waveguide and waveguide components (curved sections, complex multi-path feeds, couplers), antenna components (filters, diplexers, slotted waveguide arrays), electronically steered antenna arrays, phase matched horn antenna arrays and spiral antennas. Frequency range supported is from UHF to Q band with RF testing being part of the manufacturing process. 3D Printing is particularly well suited to RF and Microwave products where conventional manufacturing processes are impractical due to complexity or production volumes.

Typical applications include MicroGEO high throughput telecom satellites, space payloads, LEO applications, Naval and Airborne EW and Radar Systems.

Interested in Castle Microwave’s 3D printing services? Get in contact with a member of our expert team today.